In a world of rising operating costs and ever-increasing pressure on margins, simply “cutting costs” is no longer enough. Businesses need a smarter approach – data-driven cost control and performance-based decision making.

EPM is not just a planning management tool - but a "foundational piece" in the AI application journey, helping Vietnamese businesses reduce hidden costs, increase profit margins (EBITDA margin), thereby creating a solid foundation for implementing AI in business in the future context.

This article will analyze in detail EPM controls costs and optimizes profits how, the popular methods in EPM cost management, along with real-life examples from successful businesses.

What is EPM? and why does it play an important role in cost control - profit optimization?

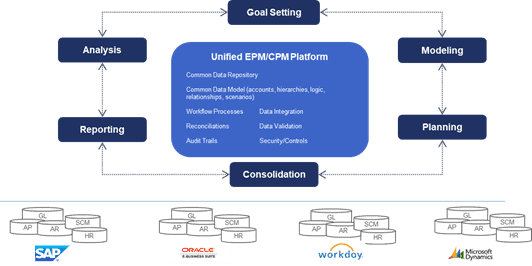

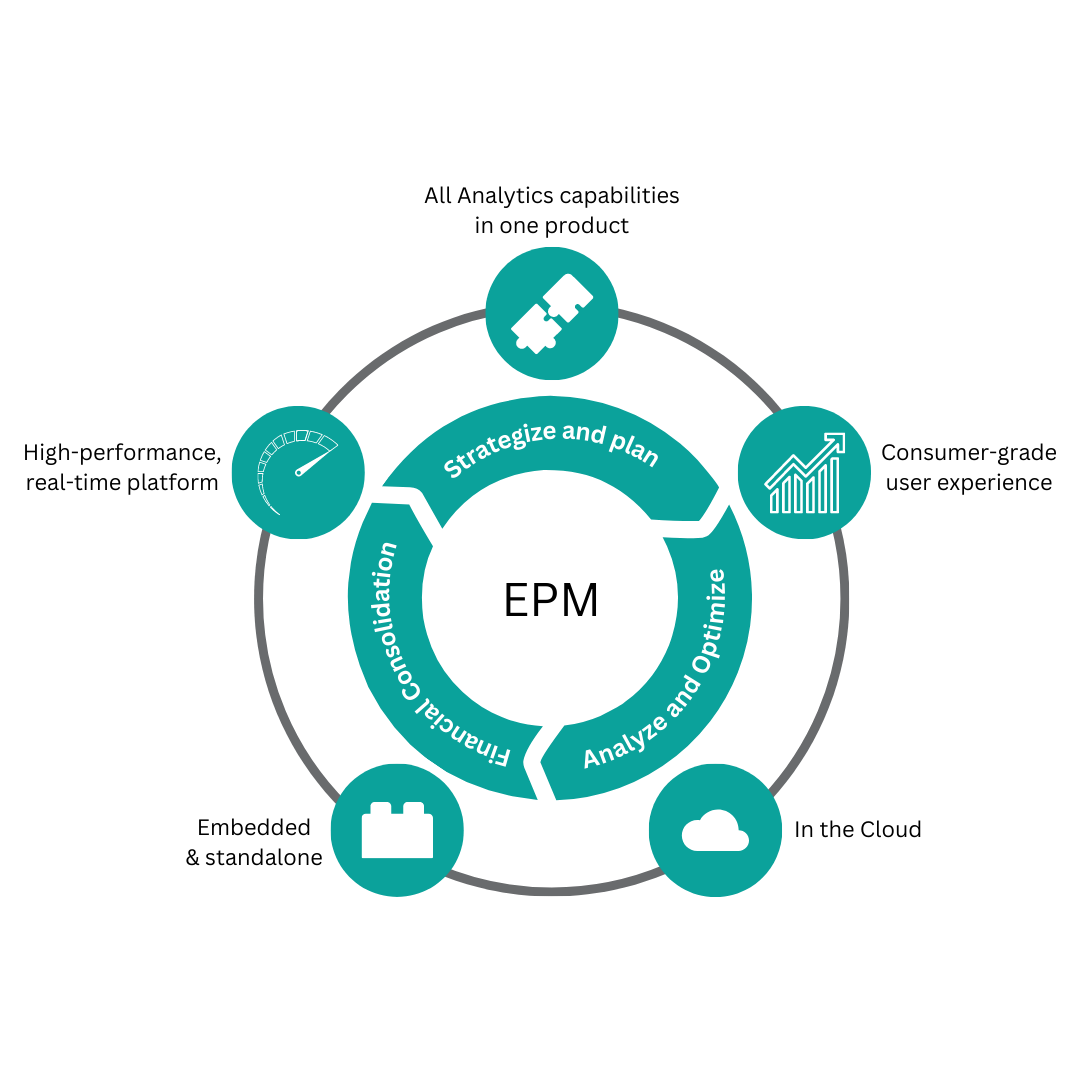

EPM (Enterprise Performance Management) – also known as CPM (Corporate Performance Management) – is a business performance management system that helps leaders monitor, analyze and forecast business results based on aggregated data from many departments. EPM is often used in financial planning and forecasting (FP&A) operations, including:

- Budgeting

- Cost Management & Profitability Analysis

- Forecasting

- Management Reporting

EPM is the bridge between ERP (operational system) and AI (predictive system) — help businesses more effective cost control, more sustainable profit optimization and data-driven decision making.

How is EPM different from ERP and Excel?

- ERP (Enterprise Resource Planning) is an operational system that records real-world transactions such as purchasing, sales, accounting, and inventory. ERP answers the question “what is happening?”

- EPM goes further: analyzing “why” and “what if”. It helps businesses plan, simulate scenarios, and control costs in real time.

- Compared to manual Excel, EPM optimizes profits by eliminating the risk of errors, duplication, and delays in data aggregation, while ensuring transparency and alignment across departments.

| Compare | Excel | ERP | EPM |

| Purpose | Manual recording & calculation | Transaction Management & Operational Data | Performance Management & Strategic Planning |

| Data | Distributed, error-prone | Actual record | Synthesize, standardize, simulate forecasts |

| Vision | Short term | Present | Long term, strategy |

| Application | Internal report | Accounting, purchasing and sales | FP&A, Cost Management, ROI Analysis |

Unlike Excel or ERP, EPM cost management help businesses understand “why are costs incurred” and “If adjusted, how would the results change?”, thereby proactively optimizing financial efficiency.

Why does EPM help businesses control costs more effectively?

EPM controls costs by automating the entire financial management cycle:

- Consolidating cost data from multiple sources (ERP, CRM, Excel, etc.) helps CFOs and FP&A departments have a 360° view of operating costs.

- Automatically compare plan and actual (Plan vs Actual), helping to promptly detect over-budget expenses.

- In-depth cost analysis (Cost by Department, Product, Project) to identify areas of waste.

- What-if Analysis: If revenue decreases by 10%, what costs need to be optimized to still ensure target profit?

- Cost Forecasting: Use historical data to predict future cost trends, supporting proactive decision making.

Thanks to that, EPM cost management not only helps save costs but also increase net profit (EBITDA margin) through more efficient use of resources.

Cost control process using EPM

EPM is not only a financial planning tool, but also the brain of business performance management. Compared to Excel or ERP, EPM helps businesses control costs tightly, forecast accurately and make data-driven decisions - an important foundation for moving forward in digital transformation and applying AI in finance.

EPM acts as a central nervous system in corporate financial management. The process includes 5 stages:

Collect cost data from ERP, CRM and other systems

EPM acts as a central hub for consolidating the company’s cost data. The system can automatically synchronize data from ERP (purchasing, accounting), CRM (marketing – sales costs) and HRM (salary, benefits).

- Ensure data is consistent and updated in real-time.

- Eliminate errors when manually synthesizing from multiple Excel files.

- Helps CFO and FP&A department have a comprehensive view of total operating costs.

Cost classification and standardization

Once the data is collected, EPM proceeds to standardize the cost structure according to internal management standards:

- Classify by cost center (department, project, branch).

- Group by cost type (OPEX – operating costs, CAPEX – investment costs).

The result is a standardized costing system that helps CFOs and internal controllers track spending against a unified standard, making it easy to reconcile and compare across units.

Budgeting expenses by department, project, branch

EPM allows for detailed budgeting for each department, project or business area:

- Directly tie budgets to operational KPIs and revenue plans.

- Support budget approval workflow feature, ensuring transparency and control right from the planning stage.

Thanks to that, businesses avoid budget overruns or spending that is not in line with business goals.

Cost forecasting and variance analysis

One of the outstanding strengths of EPM is its flexible cost forecasting ability (Rolling Forecast).

- Automatic comparison of Actual vs Budget vs Forecast, helps detect differences and identify causes of fluctuations (raw materials, labor, fixed costs, etc.).

- Update cost scenarios according to revenue or market fluctuations, helping businesses make early adjustment decisions, instead of reacting when costs exceed the allowable level.

Monitor and report costs according to KPI

EPM provides intuitive dashboards that help leaders monitor overall cost performance:

- Track key metrics like Cost-per-Department, ROI, EBITDA Margin, Cost Ratio.

- Automatically alert you when costs exceed budget or performance declines.

- Provide interactive reports to CFOs, CEOs, and investors.

Cost control methods in EPM

EPM is not only a tool for cost aggregation and reporting, but also provides advanced financial management methods to help businesses proactively control, optimize and forecast costs. Below are 3 popular methods integrated in modern EPM systems:

Zero-Based Budgeting (ZBB)

Zero-Based Budgeting is a method of building a budget from scratch, meaning that all expenditures must be explained and approved from scratch, instead of being based on the previous year's budget.

Applications in EPM:

- The EPM system allows users to enter, compare, and approve each expense according to specific goals.

- Automatically compare with KPIs to assess the necessity of each expense.

- Helps eliminate redundant costs, focusing resources on activities that bring real value.

Zero-Based Budgeting is suitable for businesses that are in the process of cutting costs, restructuring, or wanting to increase budget efficiency.

Activity-Based Costing (ABC)

Activity-Based Costing is a method of allocating costs based on cost drivers, rather than simply allocating based on a percentage of revenue or output.

Applications in EPM:

- EPM automatically identifies and analyzes cost drivers of each activity: production, marketing, logistics, customer care, etc.

- Helps managers understand which costs actually create value and which costs do not contribute to profits.

- Support smart cost-cutting decisions – without impacting overall performance.

Activity-Based Costing helps improve the accuracy of profit analysis by product, customer or sales channel. In addition, Activity-Based Costing also contributes to improving Cost Management & Profitability Analysis capabilities in the FP&A department.

Rolling Forecast

Rolling Forecast is a method of updating financial and cost forecasts continuously, usually quarterly or monthly, instead of just making a fixed plan at the beginning of the year. This method helps keep financial plans flexible, reflecting the actual situation; increases forecast accuracy and reduces the risk of overspending.

Applications in EPM:

- EPM automatically retrieves the latest Actual data from ERP to adjust the Forecast.

- Support “What-if Scenarios” simulation: if raw material prices increase by 10%, how will production costs fluctuate?

- Helps management respond quickly to fluctuations in costs, exchange rates, or market demand.

In summary, the three methods ZBB – ABC – Rolling Forecast when deployed on the EPM platform help businesses not only control costs effectively, but also transform management thinking from reactive to proactive (proactive cost management).

Benefits of using EPM to control costs

EPM is not only a cost aggregation and reporting tool, but also provides advanced financial management methods help businesses control, optimize and forecast costs proactively

Reduce redundant operating costs

- The EPM system helps detect early overspending, duplication or ineffective expenses.

- Businesses can save significantly on operating costs after 6-12 months of implementation.

Increase data transparency and accuracy

- All expenses are tracked, approved, and maintained through automated workflows.

- Reduce the risk of fraud, errors or off-budget spending.

- Ensure cost data is consistent across departments.

Support strategic decision making

- Real-time dashboard helps CFO/CEO grasp cost and profit fluctuations instantly.

- Combining cost driver analysis and scenario analysis, EPM allows simulating multiple scenarios to select the optimal strategy.

Reduce manual errors in cost management

- EPM automatically aggregates data, compares it, and generates standardized reports.

- Reduce dependence on manual Excel.

- Save time for FP&A teams, allowing them to focus on analysis instead of data entry.

Impact of EPM on Profitability and Overall Performance

EPM not only helps businesses control costs, but also directly improves profits through:

- Optimizing resource allocation: Ensure budgets are focused on activities that deliver the highest value.

- Accurately forecast revenue and expenses: Limit overstock/understock, avoid wasting working capital.

- Respond flexibly to market fluctuations: Update financial plans in real time, helping management make faster and more accurate decisions.

Illustrative example

- By simply reducing 2% of operating costs, businesses can directly increase profit margins (EBITDA margin) without increasing revenue.

- Accurate sales forecasting helps balance production and inventory, reducing warehousing costs, thereby increasing ROI and Profit-per-Project.

KPI for effective tracking

- EBITDA Margin: Profit margin before depreciation and taxes.

- ROI (Return on Investment): Investment capital efficiency.

- Profit-per-Project: Net profit per project or product.

- Operating Cost Ratio: Operating expense to revenue ratio – an indicator of overall efficiency of cost management.

Popular cost control EPM software

When choosing an EPM system to control costs, businesses should consider many factors such as:

- Assess the current state of data & internal needs (what is lacking, what needs to be improved).

- Determine a feasible budget – including implementation + maintenance + staffing costs.

- Consider solutions that are well localized for the Vietnamese market (like Sactona/Bizzi).

- Compare multiple vendors, test demos with real data; get feedback from end users.

Below are some of the most popular profit-optimizing, cost-controlling EPM parts.

Oracle EPM Cloud

It is the world's leading EPM platform, providing a comprehensive set of tools for Planning, Budgeting, Forecasting and Financial Close.

Advantage:

- Tightly integrated with Oracle ERP Cloud, supporting multinational business models.

- Strong in driver-based planning and scenario modeling.

Limit:

- High implementation and operating costs.

- Difficult to customize for small and medium businesses.

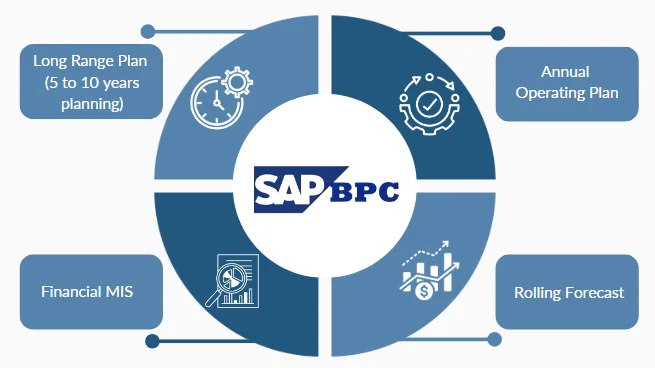

SAP BPC (Business Planning & Consolidation)

SAP's solution focuses on combining consolidation reporting and financial planning.

Advantage:

- Seamless integration with SAP ERP/S4HANA.

- Support cost control at department and cost center levels.

Limit:

- Complex implementation, long time.

- Strong dependence on SAP infrastructure, difficult to integrate external systems.

IBM Planning Analytics (TM1)

This is a planning tool based on OLAP cube technology (TM1 engine), famous for its complex data analysis and simulation capabilities.

Advantage:

- Flexible, strong in custom modeling.

- Supports AI-powered forecasting.

Limit:

- The interface is difficult to use for non-technical people.

- Requires specialized IT operations team.

Anaplan

Anaplan provides a modern EPM solution based on the Connected Planning platform, aimed at businesses with multi-departmental collaboration needs.

Advantage:

- Supports real-time, multi-scenario planning.

- Friendly and flexible interface.

Limit:

- High license cost, charged per user.

- Internet connection dependent, limited offline customization.

Workday Adaptive Planning

This is a popular cloud-based EPM solution in the service, technology, and education sectors.

Advantage:

- Fast deployment, friendly interface.

- Support dynamic reports and dashboards.

Limit:

- Limited third-party ERP integration capabilities.

- Not suitable for large manufacturing enterprises.

OneStream EPM

This is a Unified Platform for Planning, Consolidation, and Financial Reporting.

Advantage:

- Manage the entire FP&A cycle in one platform.

- Good for multinational companies.

Limit:

- Requires complex configuration and high investment costs.

Sactona (Bizzi distributes in Vietnam)

Sactona is a Japanese standard EPM solution, exclusively distributed by Bizzi in Vietnam. The software is designed to combine the flexibility of Excel with the standardization power of a modern EPM system, making it more accessible to Vietnamese businesses.

Outstanding advantages:

- Fast Deployment – ROI in 3 Months: Panasonic, Monex Group, LIXIL have demonstrated effectiveness in reducing forecasting time from weeks to days.

- Integrate with existing ERP: Easily synchronize data from SAP, Oracle, or Misa, Fast…

- Customized to the specific characteristics of Vietnamese businesses: Suitable for FP&A teams and management accountants who do not want to leave Excel completely.

- Automate the entire FP&A process: from budgeting, forecasting, to variance analysis and cost control.

- Reduce dependence on manual Excel files, increase data accuracy & transparency.

Limit:

- There is no large global user community like Oracle or SAP, but Bizzi supports consulting and localization implementation in Vietnam.

Frequently Asked Questions about EPM in Cost Control (FAQ)

Below is a Frequently Asked Questions (FAQ) section related to the topic “Cost Control with EPM”.

How does EPM help control costs?

EPM (Enterprise Performance Management) helps businesses centralize and standardize cost data from multiple sources (ERP, CRM, HRM, etc.). The system allows for budgeting, cost forecasting, variance analysis, and real-time KPI cost monitoring.

As a result, CFOs can detect overspending, evaluate ROI, and make timely spending adjustments.

Should SMEs use EPM to manage costs?

Yes. Previously, EPM was mainly for large corporations, but now there is a new generation EPM solution like Sactona – distributed by Bizzi in Vietnam – suitable for small and medium enterprises (SMEs).

Sactona enables quick deployment, a friendly Excel interface, data standardization and professional cost management without complex infrastructure investments.

How is EPM different from Excel in cost control?

- Excel: flexible but fragmented, error-prone, lacking connectivity between departments

- EPM: automatically synchronize data from multiple systems, Standardize cost center, track Actual vs Budget vs Forecast, and have intuitive dashboard.

Which module in EPM is used for cost control?

EPM usually has main modules:

- Budgeting & Forecasting: Establish and update cost budgets continuously.

- Cost Management: Classify, standardize, and allocate costs by activity (ABC).

- Variance Analysis: Analysis of the difference between actual and planned.

- Reporting & Dashboard: Track cost KPIs, EBITDA margin, ROI… in real time.

All these modules are seamlessly integrated into Sactona EPM.

Are there any real-life examples of businesses applying EPM to optimize costs?

Yes. Panasonic, Monex Group, and LIXIL have deployed Sactona EPM to consolidate data and forecast financials faster.

Result:

- Forecasting time is reduced from weeks to days.

- ROI achieved in just 3 months.

- Accuracy in cost forecasting increased by 40%.

This proves that EPM not only reduces costs but also optimizes overall performance and profitability.

Conclude

In the context of Vietnamese enterprises being increasingly pressured on operational efficiency and profitability, cost control is no longer a mere accounting task, but a survival strategy. And EPM benefits (Enterprise Performance Management) is the foundation that helps realize that strategy.

EPM provides a unified financial picture, connecting data from ERP, CRM, HRM... so that businesses can:

- Track costs in real-time, detect discrepancies and take timely action.

- More accurate budgeting, forecasting, and cost analysis helps management be proactive rather than reactive.

- Increase transparency, reduce Excel dependency, improve FP&A capabilities, and support data-driven strategic decision making.

In particular, with Sactona - a new generation EPM solution for cost control and profit optimization exclusively distributed by Bizzi in Vietnam, Vietnamese enterprises can access Japanese standard EPM technology with the following advantages:

- Fast deployment speed, friendly Excel interface, less IT dependency.

- Flexible integration with existing ERP/CRM.

- Measure and control costs – ROI – KPI on the same unified platform.

Deploying Sactona is not only a step forward in cost management, but also an important stepping stone to help Vietnamese businesses build data capabilities and be ready for the AI era.

Sign up for consultation & experience Sactona EPM – Kunconventional EPM optimizes profits and controls financial risks for your business!