Reducing business logistics costs is not just cut down, which is smart management, helping businesses optimize profits, improve operational efficiency and long-term sustainability.

Below are 10 effective strategies that help businesses not only reduce direct costs but also increase brand value, meet ESG requirements and develop long-term.

Logistics costs – The burden that “erodes” business profits

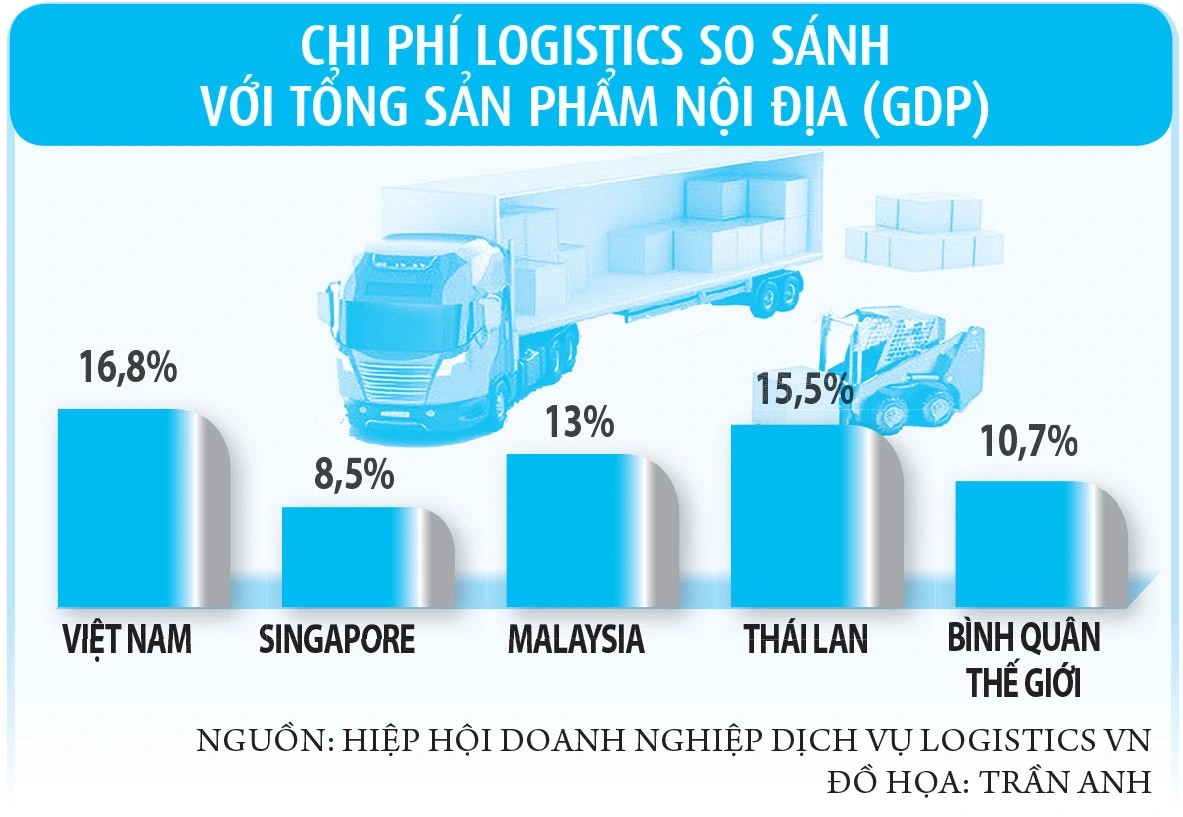

In Vietnam, Logistics costs are accounting for 16-201% of GDP., significantly higher than the level 10–12% of ASEAN countriesThis makes manufacturing and distribution businesses the most heavily affected group, especially in transportation costs and inventory costs.

However, most CFOs and finance teams only see “on the books” expenses such as:

- Shipping fee

- Warehouse fees

- Order processing fee

Without seeing the hidden cost layer underneath – which silently eats away at monthly profits:

- Waiting time for vehicle, waiting to pick up goods

- Late or incorrect delivery fees

- Returned goods - cancelled due to expired storage

- Operational risk fee

- Opportunity cost from lost orders and lost customers

Businesses can only increase sustainable profits by optimizing logistics with data and automated control mechanisms. Business cost management It's not about cutting corners – it's about optimizing operations so that every dollar spent creates more value.

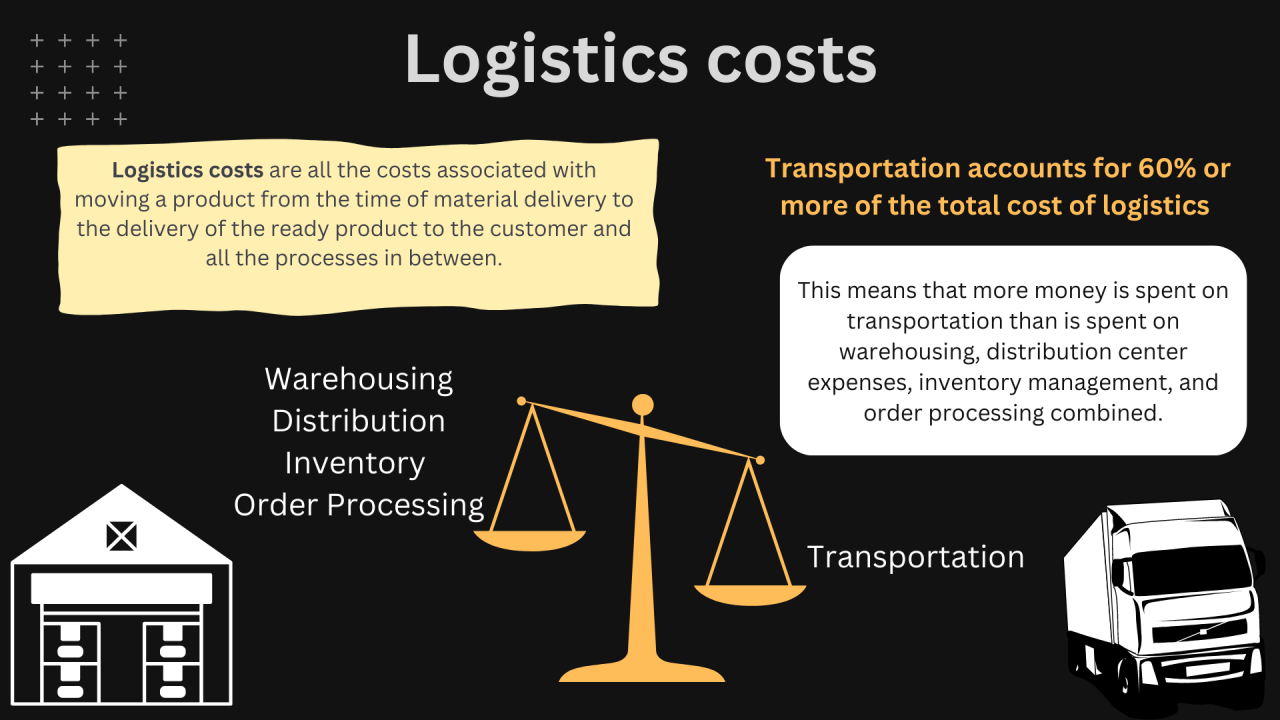

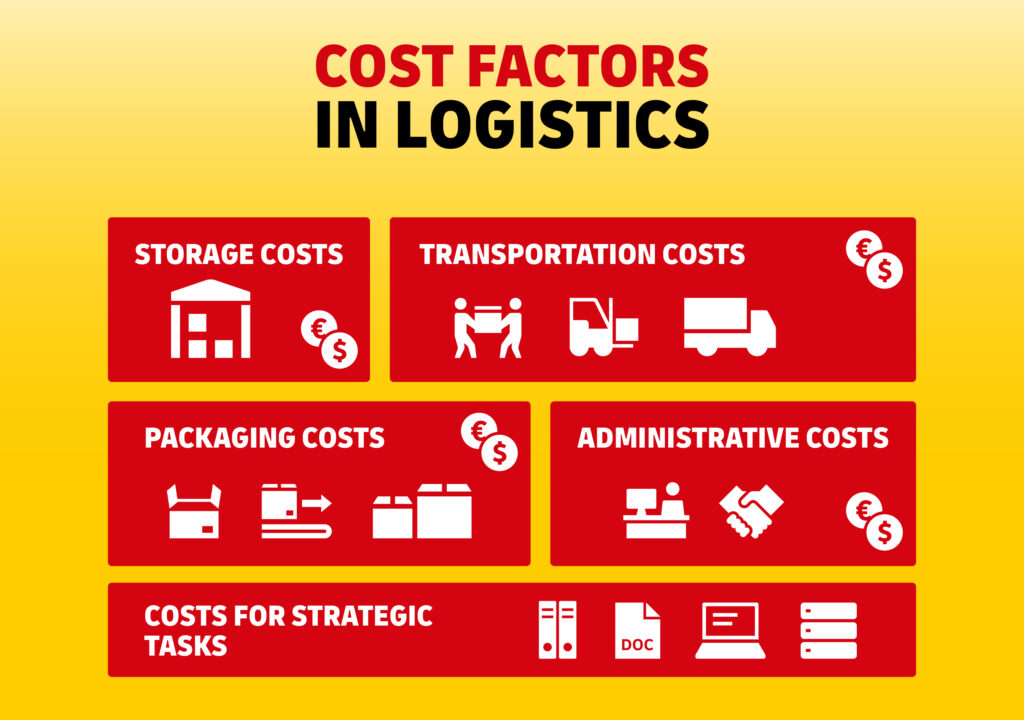

What does logistics cost include? – Analyze the components to know where to cut

To optimize and reduce corporate logistics costs, CFOs need to see the entire cost structure – rather than just focusing on shipping rates. Each component has the opportunity to optimize if measured by data rather than by gut feeling.

1. Transportation costs

This is the largest cost group in the entire logistics operation. and is also where businesses are most susceptible to "cost leakage".

Any small deviation in route, schedule, fuel consumption or rental price can create huge differences when multiplied by thousands of trips per month. Transportation costs account for 50–60% of total logistics costs.

Include:

- Fuel

- Driver salary & allowance

- Vehicle depreciation & maintenance

- Bridge, parking and parking fees

- 3PL (3rd party logistics) fee

Common Leak Points

- The car ran empty for many kilometers

- Late flight → SLA penalty

- Choosing a suboptimal route wastes fuel

- No control over outsourcing prices by COD/trip/ton-km

2. Warehouse & Inventory costs

Warehouses are both assets and a source of great financial risk. High inventories kill capital, but low inventories cause out-of-stocks.

Without a real-time forecasting, measurement, and control system, businesses often incur hidden costs such as loss, slow order processing, data discrepancies, and poor inventory turnover. This is a group of costs that is less visible but directly affects cash flow and profit margins.

Warehousing & inventory costs are around 20–25%.

Include:

- Rent/buy warehouse space

- Warehouse operations staff

- Energy, security, insurance

- Cost of slow-moving inventory

- Damage due to poor storage

Leak point

- Incorrect forecast → high inventory → increased cost of capital

- Unscientific warehouse layout → slow order processing time → increased labor costs

- Manual inventory reporting → data discrepancies

3. Packaging & Handling Costs

Although it only accounts for 5–10%, this cost group is The part of business that is most easily overlooked but wastes the most.

Non-standardization of materials, lack of control over packaging processes, and over-reliance on manual labor cause packaging costs to increase without improving efficiency. For businesses with large orders, optimizing this cost group helps significantly reduce total logistics costs.

Include:

- Packaging, packaging materials

- Order processing staff

- Wrapping equipment, tape, pallet

Leak point

- No standardization of materials → waste of 10–20% of packaging

- Too many manual processes → low productivity

4. Management costs & procedure

This is the group of costs related to paperwork, procedures, legal and system connection — the capital is not large per order, but when an error occurs, the consequences are very serious.

A delay in a document can delay a container, leading to a series of storage costs, late penalties, late delivery, and loss of customers. Businesses without standard processes and digital records management systems are most at risk in this cost group.

Include:

- Customs, C/O, inspection

- Cargo insurance

- Documentation fees: bill of lading, inspection papers

- IT systems, EDI, connection software

Leak point

- Late one document → late one shipment → increased chain cost

- No standardization of documents → time consuming reconciliation

5. Hidden Costs — the things that eat away at profits

In reality, businesses don’t always lose money because of obvious expenses. Many of the “cuts” in operations come from costs that we don’t pay for. not immediately visible, but silently erodes profit margins every day.

These are small expenses that accumulate continuously, are not measured, are not warned about and are not controlled in time.

- Obsolete inventory → increased capital costs & reduced turnover

- Vehicles waiting too long to be unloaded → increase idle time & labor

- Empty car on the way back → waste up to 30% in fuel costs

- Incorrect shipping invoice → time consuming reconciliation → late payment

- Lost orders due to late delivery → opportunity cost

Many businesses lose 10–15% in profits simply because of hidden costs they don't measure.

Why are logistics costs of Vietnamese enterprises always higher than those in the region?

Logistics costs in Vietnam are currently at 16-20% of GDP, significantly higher than in ASEAN countries (10-12%). The reason comes from a combination of objective and internal factors of the enterprise.

1. Objective reasons

Here are some objective reasons:

| Element | Affect |

| Logistics infrastructure is not yet synchronized. | Roads, railways and seaports lack connectivity; intermodal transport is time-consuming and costly. |

| Fuel prices & container costs continue to rise | Fluctuating fuel prices, container rental costs, road and port fees directly increase transportation costs. |

| High port fees and transportation service fees | The port system and logistics services are not yet competitive, leading to increased service costs, affecting terminal costs. |

2. Internal causes of the enterprise

Some internal reasons for Vietnamese enterprises' logistics costs are always higher than those in the region:

| Element | Affect |

| Lack of real-time monitoring system | Unable to control costs for each leg, leading to fuel loss, late delivery penalty costs, and empty vehicles. |

| Manual warehouse management, inaccurate inventory | Slow inventory turnover, increased capital costs, financial accounting errors, lost sales opportunities. |

| Lack of connection between logistics - accounting - finance | Not knowing where costs arise, difficult to reconcile, easy to lose and hidden costs. |

| No KPI to measure performance | Not measuring cost per order, OTD% (On Time Delivery), inventory turnover → difficult to identify leakage points and optimization opportunities. |

Many businesses look at transportation and warehousing costs on the books, but don't realize the hidden costs underneath, silently eating away at profits.

To reduce business logistics costs to the optimal level like ASEAN countries, businesses need to integrate logistics - warehouse - accounting data, set up KPIs to measure actual efficiency, and optimize each stage with technology and automation.

Cut Transportation Costs – The First Lever to Reduce Total Logistics Costs by 10–15%

Transportation costs account for 50–60% of total logistics costs, so optimizing transportation is the first step and easy to measure efficiency. There are many ways to reduce business logistics costs while ensuring service quality:

1. Route Optimization

- Using smart routing software (AI, algorithms to optimize distance, time, delivery density).

- Benefits: reduce 10–12% fuel cost, save 20% transportation time.

- For example, AI calculates priority delivery routes, avoiding rush hours, making the most of trucks.

2. Order Consolidation

- Consolidate small shipments into large ones → maximize vehicle load capacity, reduce empty trips.

- Limit empty vehicle running, reduce fuel waste and labor costs.

- Benefits: 5–10% reduction in transportation costs if implemented correctly.

3. Hybrid Logistics

- Combine road – sea – air to choose the most economical solution.

- Outsource to 3PL during peak season → reduce fixed costs and risks.

- For example: transporting bulky goods by sea, express goods by road.

4. Green Logistics (Green Logistics)

- Use electric or fuel-efficient cars, consumption monitoring via IoT.

- Benefits: 5–8% reduction in operating costs, while enhancing sustainable image.

Reduce warehouse and inventory costs – Cut “dead costs” in warehousing

Warehouse and inventory costs account for 20–25% total logistics costsMany businesses still waste a lot due to manual inventory management, space optimization and lack of effective measurement tools. To “cut dead costs” in warehousing, the following solutions can be applied:

1. Scientific inventory management

- Just-In-Time (JIT): Reduce excess inventory, only stock when needed.

- ABC Analysis: Classify fast-moving and slow-moving goods to prioritize management and optimize capital.

- Benefits: reduce capital costs, limit outdated or expired goods.

2. Optimize warehouse space

- Arrange warehouse according to import and export frequency: Reduce travel time, increase operating efficiency.

- Smart shelves & IoT sensors: Automated inventory, reduced errors, reduced manual labor.

3. Application of technology

- HWMS system: Real-time inventory tracking, quick reporting of quantity, location, and shipment.

- Cross-docking: Fast in-out goods, reduced storage time, limited long-term storage costs, reduced business logistics costs.

4. Important KPIs to measure performance

- Inventory Turnover: Inventory Turnover

- Days on Hand: Average number of days of inventory

- Occupancy Rate: Warehouse space utilization rate

It can be seen that most of the costs of warehouse rental, electricity, insurance, warehouse cleaning are often scattered and difficult to summarize. When optimizing warehouse and inventory, businesses not only reduce costs but also reduce working capital, improve cash flow and operating efficiency.

Automating Logistics Processes – How to Reduce Costs by 20–30% While Speeding Up Operations

To reduce costs and speed up operations at the same time, many businesses are applying digital technology and automation. The solution not only cuts direct business logistics costs but also reduces hidden costs, improving the efficiency of the entire logistics chain.

1. Application of digital technology

| Technology | Application | Benefit |

| AI & RPA | Processing of documents, freight bills, and automatic container tracking | Save time checking, reduce errors, quick reconciliation |

| IoT | Attach sensors to measure temperature, location, and flight delay warnings | Real-time monitoring, proactive problem handling, reducing late penalty costs |

| Big Data / Predictive Analytics | Forecasting demand and traffic flow | Reduce inventory, optimize routes, increase on-time delivery rate |

2. Outsourcing logistics services (3PL, 4PL)

- Reduce infrastructure investment costs: warehouse, vehicles, technology.

- Leverage the 3PL provider's existing transportation and warehouse network.

- Businesses focus on the core: production, sales, marketing.

- Benefits: save 10–15% in operating costs compared to self-investing in infrastructure.

3. Optimize packaging

- Reduce package weight, use recycled materials, standardize packaging.

- Reduced direct shipping costs 3–5% and reduced warehousing costs due to smaller storage space.

4. Training digital logistics personnel

- TMS/WMS operator, understand KPI cost-performance.

- Reduce manual errors, increase productivity and accuracy.

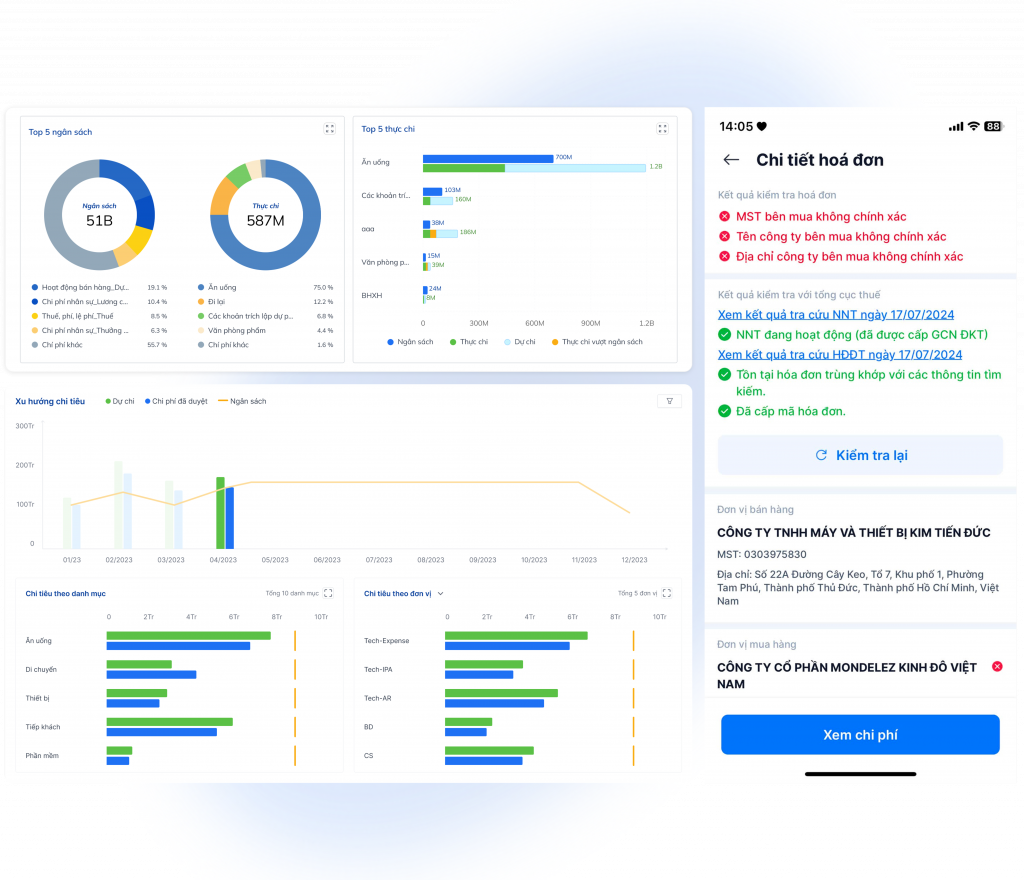

Cutting Business Logistics Costs with Data – A Modern CFO Perspective

In many businesses, optimizing operations does not mean controlling costs. Many CFOs only see costs on the books without measuring actual efficiency, leading to hidden losses and inaccurate investment decisions.

To manage and reduce business logistics costs effectively, transparently and based on data, it is necessary to focus on the following solutions:

1. Create a set of logistics and financial KPIs

Some important KPIs for CFOs to track:

- Cost per ton-km: Transport cost per ton-kilometer

- Cost per Order: Operating cost per order

- Logistics Cost Ratio (%): Logistics cost/revenue ratio

This KPI helps businesses see where costs are exceeding or falling below the standard, thereby optimizing costs for each route, each type of goods, each project.

2. Compare actual expenses with budget (Budget vs Actual)

- Track logistics costs in real time and compare with the planned budget.

- Identify discrepancies, causes and make timely adjustments.

3. Evaluate ROI of technology investment

- Investments in TMS/WMS, operational automation software need to be evaluated based on actual financial benefits: save costs, shorten delivery time, reduce errors.

- The clearer the ROI, the easier it is for the CFO to convince the Board of Directors to expand the technology application.

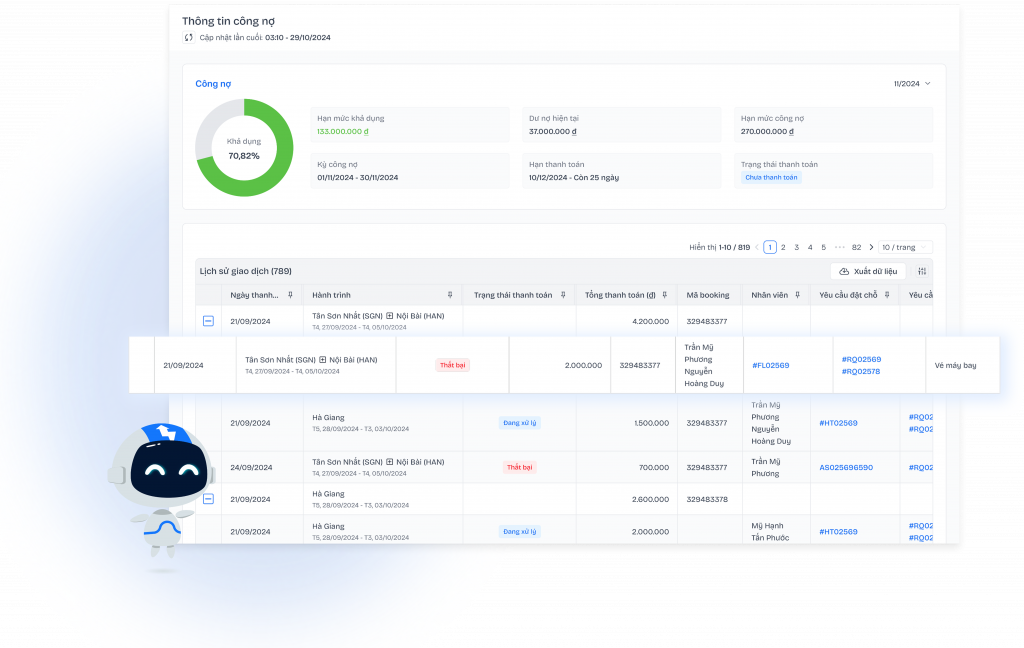

With Bizzi Expense, CFO can:

- Assign each logistics transaction to the corresponding cost center

- Track logistics cost/revenue ratio in real time

- Get automatic alerts when transportation costs exceed your budget

Thanks to online data and clear KPIs, modern CFOs can not only control costs but also make strategic decisions, optimize operations and improve business profits.

Bizzi – Automate logistics cost control for businesses

Logistics costs are often scattered, difficult to summarize and prone to hidden losses. Bizzi helps businesses automate the control, reconciliation and transparency of logistics costs, from transportation, warehousing to related costs.

1. Automatic processing of logistics invoices

- Warehouse rental invoices, transportation fees, road tolls... are automatically downloaded, read and checked for validity by Bizzi Bot.

- Eliminate manual operations, reduce errors and processing time.

2. 3-Way Match

- Compare Invoice ↔ PO ↔ Receipt (GR)

- Detect:

- Invoice error

- Duplicate invoice

- Price difference

- Help CFOs and accountants quickly confirm accurate costs.

3. Check the supplier

- Automatically look up Tax Code and status of transport business on tax system.

- Ensure legal and valid costs according to regulations.

4. Budget & Spending Control

- Allocate budget to each route, warehouse or logistics project.

- Overspending warning system and real-time reporting for CFO.

- Easily track cost/logistics revenue ratio in real time.

5. Actual results

- Reduce logistics invoice processing time by 70–80%.

- Cost transparency down to each order, route or supplier.

- Reduce financial operating costs 20–25%, helping businesses optimize cash flow and profits.

Sustainable Logistics – Reducing Costs and Emissions Go Hand in Hand

Nowadays, businesses are not only concerned about logistics costs, but also about environmental impact. Applying Green Logistics helps businesses save costs and improve their ESG reputation.

1. Green Logistics

- Use fuel-efficient vehicles and optimize load capacity.

- Reduce CO₂ emissions, reduce fuel and operating costs.

2. Paperless Logistics

- Eliminate paper documents and switch to electronic invoices and documents.

- Reduce administrative costs, increase reconciliation speed, reduce errors.

3. Circular Logistics

- Reuse packaging, pallets, packing materials.

- Reduce material costs, warehouse costs and waste disposal costs.

4. Carbon KPI

- Track CO₂ costs per order as a performance indicator.

- Help CFO and Board of Directors evaluate economic and environmental performance in parallel.

Bizzi not only helps cut business logistics costs but also increases the speed and transparency of logistics operations, turning cost data into a strategic tool for CFOs. Fully digital invoices and documents help businesses:

- Cost transparency

- Real-time reconciliation

- Meet ESG and compliance criteria

- Combine financial management with sustainability strategy.

Conclude

Logistics costs account for a large proportion of a business’s total operating costs, from transportation, warehousing, inventory, packaging to hidden management costs. However, blindly cutting business logistics costs does not help optimize profits – on the contrary, it can affect service quality and operating speed.

Cut business logistics costs not by reducing staff or vehicles, but by optimizing each cost line based on real data and automating processes.

To reduce costs effective and sustainable, businesses need:

- Optimize each cost line based on actual data, rather than guesswork.

- Technology application & automation in transportation, warehousing, invoicing and reconciliation.

- Set KPIs and measure performance logistics along with investment costs and ROI.

- Combining sustainable strategies (Green Logistics, Paperless, Circular) to reduce emissions and material costs.

With Bizzi, businesses can automate logistics cost management to make costs transparent, control budgets by route/warehouse/project, detect hidden costs, and create a database for fast and accurate strategic decision making.

- Discover how Bizzi helps businesses control logistics costs in real time – from freight invoices to financial reports: https://bizzi.vn/dat-lich-demo/

- See more articles about Top 27 Cost Management Software here